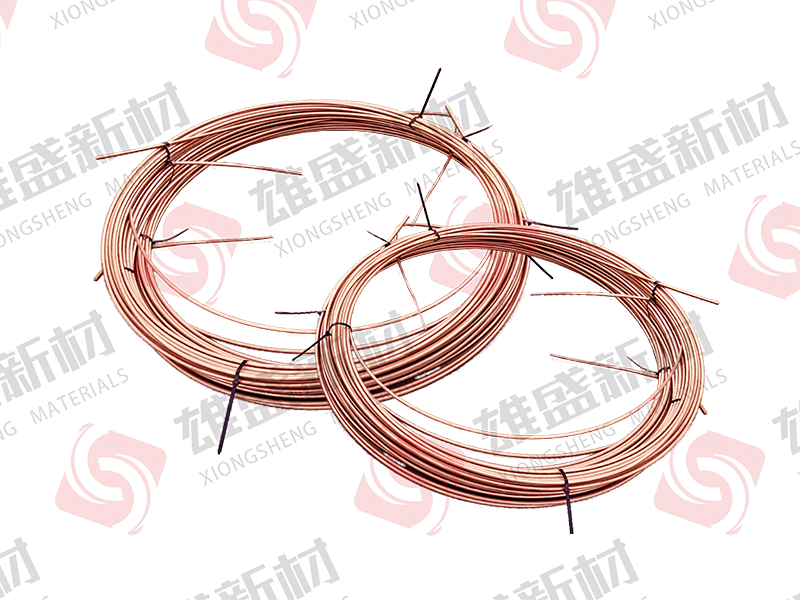

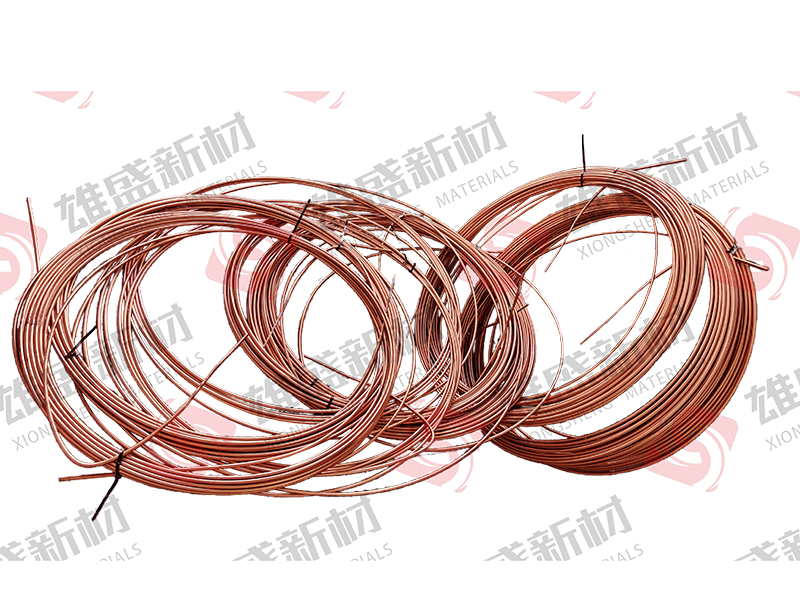

C18000 nickel-chromium-silicon copper wire

Performance advantages of C18000 nickel-chromium-silicon copper wire:

- High strength

- Good electrical and thermal conductivity

- Wear and corrosion resistance

- Heat treatment performance

- Suitable for processing into various shapes

- Fatigue resistance

Key words:

Classification:

Product Description

Our company can provide you with a range of products.

Diameter: φ0.1mm and above

Performance advantages of C18000 nickel-chromium-silicon copper wire:

High strength

Good electrical and thermal conductivity

Wear-resistant and corrosion-resistant

Heat treatment performance

Suitable for processing into various shapes

Fatigue resistance

Application fields of C18000 nickel-chromium-silicon copper wire:

C18000 nickel-chromium-silicon copper wire composition parameters:

| Product name | Copper Cu | Nickel Ni | Chromium Cr | Silicon Si | Iron Fe | Aluminum Al | Beryllium Be | Cobalt Co | Manganese Mn | Lead Pb | Zinc Zn | Magnesium Mg | Zirconium Zr | Phosphorus P | Other impurities | Introduction |

| C18000 nickel-chromium-silicon | Remaining amount | 1.8-3.0 | 0.1-0.8 | 0.4-0.8 | 0.15≤ | 0.65 | This alloy has good electrical conductivity, thermal conductivity, high strength and hardness, as well as excellent wear resistance and corrosion resistance. C18000 alloy is widely used in fields such as resistance welding electrodes and injection molds. |

Production process flow of C18000 nickel-chromium-silicon copper wire:

Batching - Melting - Composition analysis - Casting - Milling - Hot rolling/hot forging - Solution treatment - Cold rolling/cold forging - Aging - Leveling - Pickling - Inspection - Testing - Finished product.

Related Products

Get a product quote

Our staff will contact you within 24 hours (working days), if you need other services, please contact us!

Mobile:

Mobile:

Messages

Free access to product solutions

Copyright © 2024 Jiangsu Xiongsheng New Material Co., Ltd.

Business License