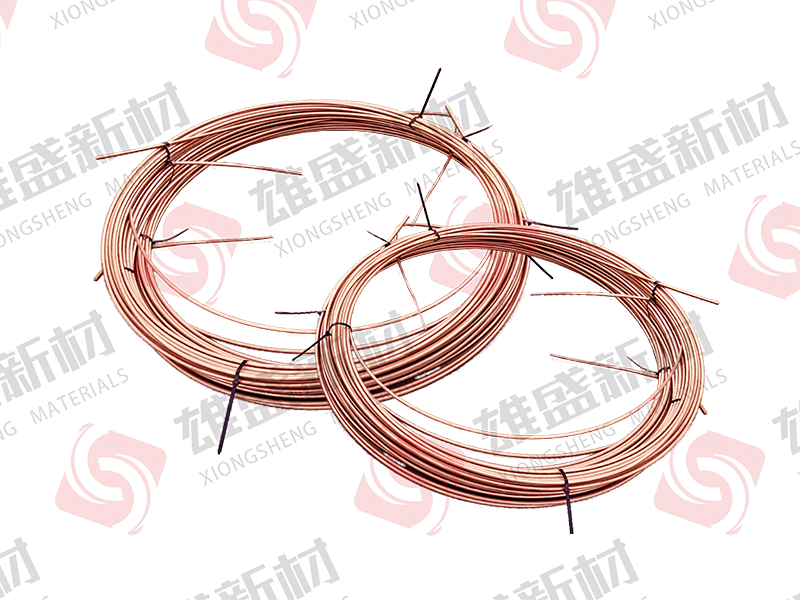

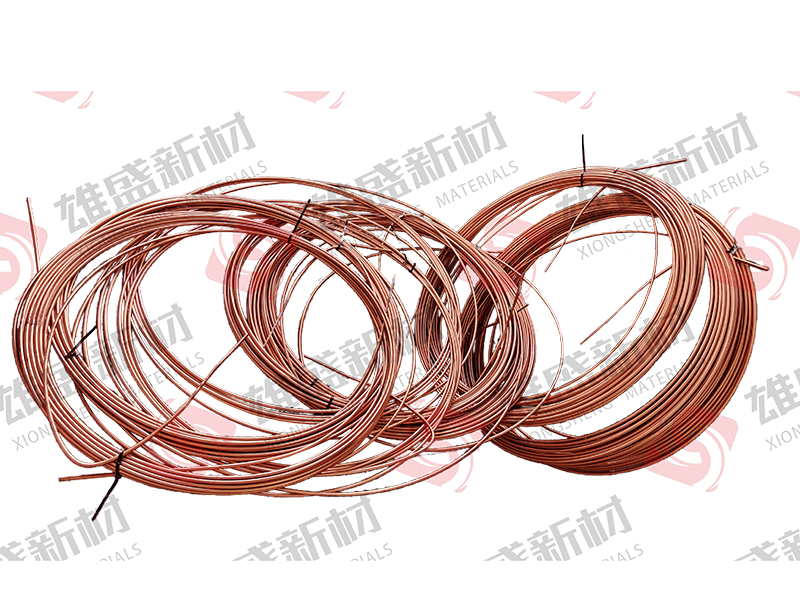

C17500 Beryllium-Copper Wire

Performance advantages of C17500 beryllium-copper wire:

- High strength

- Good electrical and thermal conductivity

- Wear and corrosion resistance

- Heat treatment performance

- Suitable for processing into various shapes

Key words:

Classification:

Product Description

Our company can provide you with a range of products.

Diameter: φ0.1mm and above

Performance advantages of C17500 beryllium-copper wire:

High strength

Good electrical and thermal conductivity

Wear-resistant and corrosion-resistant

Heat treatment performance

Suitable for processing into various shapes

Application fields of C17500 beryllium-copper wire:

Performance parameters of C17500 beryllium-copper wire:

| Product name | Copper Cu | Nickel Ni | Chromium Cr | Silicon Si | Iron Fe | Aluminum Al | Beryllium Be | Cobalt Co | Manganese Mn | Lead Pb | Zinc Zn | Magnesium Mg | Zirconium Zr | Phosphorus P | Other impurities | Introduction |

| C17500 beryllium-copper | Residual | 0.015 | 0.2≤ | 0.1≤ | 0.2≤ | 1.8-2.1 | 0.6 | Trace | 0.005≤ | Trace | 0.01≤ | This alloy has excellent mechanical properties due to its beryllium content, including high strength, hardness, elasticity, and conductivity, as well as good corrosion resistance and non-magnetic properties. The C17500 alloy is widely used in the manufacturing of precision springs, contactors, fuses, clock parts, and other engineering fields that require high performance. |

Production process of C17500 beryllium-copper wire:

Batching - Melting - Composition analysis - Casting - Milling - Hot rolling/hot forging - Solution treatment - Cold rolling/cold forging - Aging - Leveling - Pickling - Inspection - Testing - Finished product.

Related Products

Get a product quote

Our staff will contact you within 24 hours (working days), if you need other services, please contact us!

Mobile:

Mobile:

Messages

Free access to product solutions

Copyright © 2024 Jiangsu Xiongsheng New Material Co., Ltd.

Business License